In the fast-paced world of warehouse management, the challenges of handling fragile items, irregularly shaped items, and resolving inventory discrepancies have long been a source of concern. Traditional methods often rely heavily on human intervention, leading to inefficiencies, errors, and increased risk of damage to delicate products. However, with advancements in technology, particularly in the realm of artificial intelligence and robotics, new opportunities for innovation and automation have emerged.

Imagine a fulfillment center for an online retailer that sells a variety of products, including electronics, home décor items, and kitchenware. One of the items in high demand is a delicate crystal vase, often purchased as a gift for special occasions.

When an order for the crystal vase comes in, the fulfillment process begins. In this fulfillment center, robots are primarily responsible for picking and transporting items from the inventory shelves to the packing area. However, when it comes to delicate items like the crystal vase, robots may struggle to handle them safely due to their fragility.

It’s evident that many companies are responding to the challenge of fragility identification and handling through a combination of human oversight and automated systems. However, this approach still relies heavily on manual intervention, which can be time-consuming, labor-intensive, and prone to human error. To address these challenges more effectively, companies can explore innovative solutions that leverage advanced technologies such as robotics, artificial intelligence, and automation.

Some of the critical hurdles faced in today’s market concerning fragility revolves around ensuring the safe handling of delicate items throughout the supply chain.

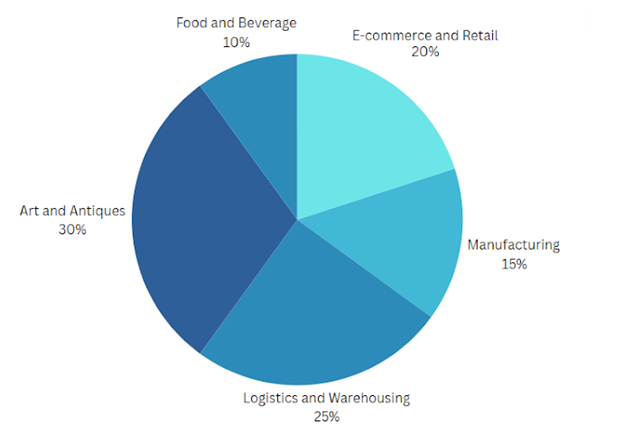

There are various section of the industries who are facing this issue of making the process fully automation without the human intervention.

Now, Join us as we explore the technical marvels driving this revolution and discover how these advancements are transforming industries worldwide without any human intervention.

Computer Vision and Object Recognition Algorithms:

The advanced computer vision algorithms that enable automated systems to recognize and classify fragile items based on visual cues such as shape, texture, and color. The use of convolutional neural networks (CNNs) and deep learning techniques for accurate and efficient object recognition in warehouse environments help to detect and classify the objects. These can also be helpful in identifying irregular shaped items and distinguish between different types of inventory items, enabling autonomous sorting and handling.

Robotic Manipulation and Grasping Technologies:

The innovative robotic manipulation and grasping technologies designed to handle fragile items with precision and care play a vital role in building these systems. Moreover, the use of tactile sensors, force feedback systems, and adaptive grippers allow robots to adjust their grip and handling techniques based on the fragility and shape of the items.

Smart Packaging Solutions:

The smart packaging solutions equipped with sensors and actuators that monitor the condition of fragile items during transit where the solutions can detect and respond to environmental factors such as temperature changes, humidity levels, and impact forces to ensure the integrity of fragile items. Furthermore, the use of RFID tags and QR codes on packaging to track and trace individual items throughout the supply chain, reducing the risk of inventory discrepancies.

AI-Powered Inventory Management:

Machine learning algorithms are revolutionizing inventory management by predicting and preventing discrepancies before they occur. Anomaly detection algorithms analyze historical data and real-time transactions to identify discrepancies in inventory levels or item counts, allowing warehouses to take proactive measures to maintain accuracy. With AI-powered inventory management, warehouses can say goodbye to stock outs and overstocking, optimizing inventory storage and retrieval processes for maximum efficiency.

Integrated Warehouse Management Systems:

The Integrated warehouse management systems (WMS) combine various technologies and systems into a unified platform, enabling seamless communication and coordination between automated equipment, warehouse personnel, and external stakeholders. With integrated WMS solutions, warehouses can streamline operations, improve overall efficiency, and ensure accurate inventory management without the need for manual intervention.

Feel free to share your thoughts and experiences with on-demand computing in the comments below! Let’s get the conversation started.